ACT-TSA Total Station Autocollimator

- Integrates an autocollimator and laser beam profiler in one system.

- Motorized focusing with multi-wavelength operation from UV to NIR.

- Measures and aligns laser arrays (VCSELs), LiDARs, and optical assemblies.

- Ensures sub-arcsecond angular accuracy (0.01 arc sec or better).

- Aligns mechanical and optical axes and projects virtual targets at defined distances.

- Ideal for AR/VR, satellite, and optomechatronic applications.

- Rugged, permanently aligned design for high stability and precision.

- Connects via RS-232 or TCP/IP with full data and video recording software .

Electronic Autocollimators:

- ACT-25B Electronic Autocollimator

- ACT-25FO Autofocusing Electronic Autocollimator

- ACT-25LA Laser Analyzing Electronic Autocollimator

- ACT-HR High-Resolution Electronic Autocollimator

- ACT-HR100 High-Resolution Electronic Autocollimator

- ACT-WF Wide-Field Electronic Autocollimator

- ACT-TSA Total Station Autocollimator

Related Products:

The new ACT-TSA is designed to expand usability in photonics applications, including AV/VR.

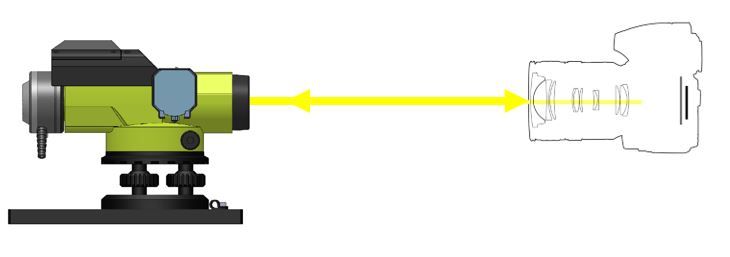

The Total Station Autocollimator uniquely offers a laser beam profiler integrated into the system. It is complemented by motorized focusing of the autocollimator, which also operates with wavelengths from UV to NIR and beyond.

All optical elements, including multi-wavelength sources, are precision-mounted, and the entire instrument is rugged and stable, providing accurate beam pointing and robustness for various applications.

By maintaining the alignment of the beam profiling device with the autocollimator's line of sight, a new application field is available for integrating and aligning lasers with optical elements and telescopic sights. Moreover, by integrating multiple independent beam profiling measurements from a single sensor, a significant leap forward is achieved for measuring of VCSEL arrays and their alignment with specific optical assemblies.

Applications span from AR/VR goggles and 3D LiDARs to satellite alignment and the inter-alignment of multiple optical elements combined with electronic sensors and lasers. The capabilities of the PLX TSA instrument are extensive, encompassing optical and laser alignment, illuminated target projection, boresighting, non-contact mechanical measurements in a plane perpendicular to its line of sight, laser characterization, laser and LiDAR characterization, power measurement, and distribution, analysis of complex assemblies, among many others.

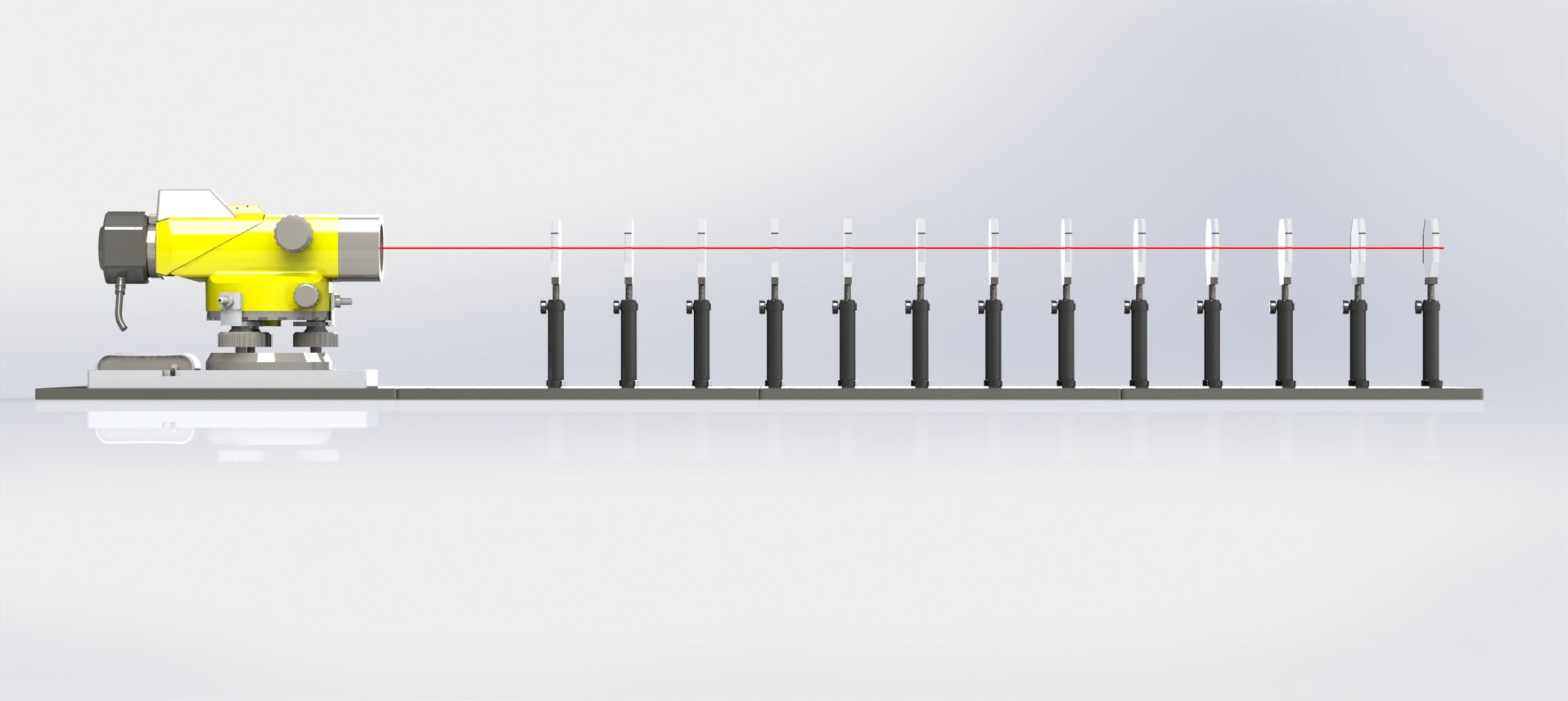

Machinery Alignment

The Autocollimator/Telescope can be used for checking the accuracy of machine slides. To check the slides, mount a mirror to the machine table. The mirror is facing in the direction of travel. The autocollimator is aligned to the mirror, and the table is then moved either continuously or in discrete steps. Any error in the movement of the table shows up as the reticle image moving.

Optical Testing

The electronic autocollimator can be used for testing various optical components. Some can be measured directly, and others would require the use of supplemental optics.

When using the autocollimator mode, it is important to understand the display readout. The autocollimator scale is set up to measure mirror tilt, not the beam angle. When a mirror is tilted, the reflected beam is deviated by twice the angle of the tilt.

Boresighting

Boresighting is the aligning of a targeting system or systems with the barrel of a weapon, or the co-alignment of different targeting systems (visible and infrared). Boresighting will typically require some additional set-up/equipment. This could take the form of an accurate translation stage or an LTHR or periscope possibly equipped with a beam splitter.

The set-up here is highly dependent on the configuration and number of objects being bore-sighted.

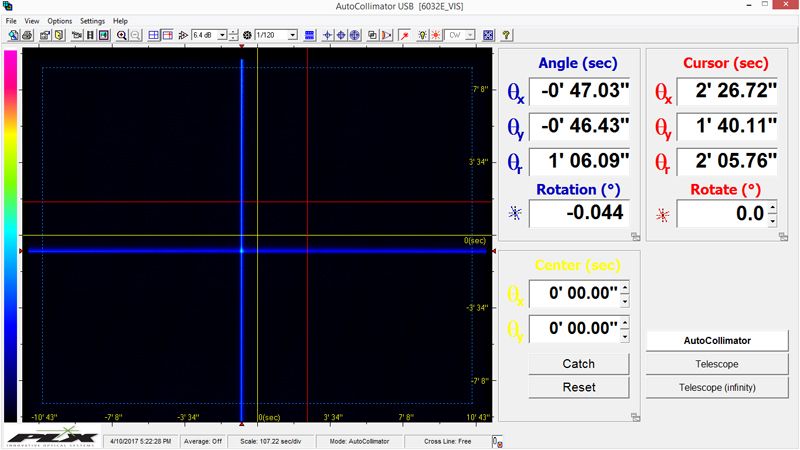

Software

The software automatically displays angle deviation and can give the relative position of multiple targets.

Data logging is supported and can be configured to record for a predetermined time or a fixed number of data points. The recording interval can also be set. The data can be saved to a file or streamed to a remote location via RS-232 or TCP/IP. The communication setting for both RS-232 and TCP/IP is fully configurable from the software.

| Specification | Value | 3D Models & Diagrams |

|---|---|---|

| FoV Autocollimator | ±60’ (H) x ±40’ (V) | Click Here |

| FoV Beam Profiler | ±120’ (H) x ±80’ (V) | |

| Clear Aperture | 36mm | |

| Resolution | 0.005 arc second | |

| Accuracy | 1.0 arc second | |

| Light Source | Switchable RGB Switchable RG/IR Special order: 1060 / 1310nm | |

| Line of Sight Retention as Function of Focusing | ± 2.5 seconds | |

| Focusing Distance | Calibrated from 18 cm to infinity | |

| Built in coarse aiming Laser Pointer | 650 nm power <1.0 mW Class 2 laser product, IEC60825-1 | |

| Spectral Response | 350 - 1310 nm (Telescope Mode) | |

| Resolution (H x V pixels) | 8200 x 5600 | |

| Gain Control | x400 | |

| Exposure Speed | 39 μsec up to 2 sec | |

| Frame Rate | 50 fps, a few hundreds on ROI mode | |

| Pixel Size | 2.3 µm x 2.3 µm (binning 1) | |

| Pixel Bit Depth | 8/16 bits | |

| Background Subtraction | User activated | |

| Trigger | Internal Software | |

| Interface | USB 3.0, Windows 8/10/11 (32 &64 bit) |

Metrology System for Inter-Alignment of Lasers, Telescopes, and Mechanical Datum: Poster Presentation at OPTIFAB.

Advances in sensor technology have opened the door to new measuring instruments, initiating the development of the new PLX, ACT-25 and ACT-HR Electronic Autocollimator and Alignment Telescope Systems.

The technology is based on autocollimation principles combining laser beam collimation and direction measurement, accurate telescopic measurement, focusing techniques with sophisticated software and computing techniques. Of special interest is the laser analyzing autocollimator since it combines laser-analyzing technology with angular reflection technology.

PLX’s "Metrology System for Inter-Alignment of Lasers, Telescopes, and Mechanical Datum” abstract / manuscript accepted at SPIE for inclusion in their Library of Technical Papers.

In modern scientific and industrial laser applications, inter-alignment of multiple optical devices is frequently a basic requirement to meet a certain specification and performance.

However, the designed optical system combining mechanical elements, lasers and optical sights in various wavelengths frequently deviates from specified