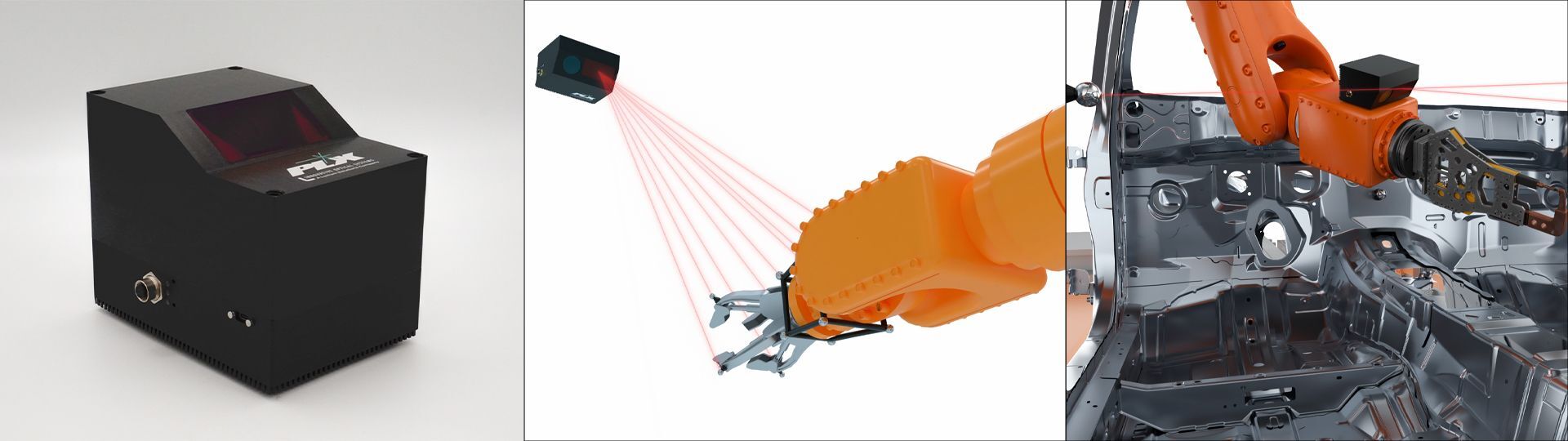

Orthogonal Laser Metrology Module (O-LAMM)

- Perfect for high-precision alignment, robotic tracking, and in situ metrology.

Designed to deliver:

- High-Speed Scanning (up to 100 Hz)

- Multi-Target Tracking with Retro-Reflective Markers

- Excellent Thermal & Mechanical Stability

- Compact, Rigid Monolithic Design

- Key Features

- Range:15m

- Field of view: 50° x 60°

- Accuracy: <5 arc sec

- Frame rate: 100 fps with 20 targets

Related Technologies

PLX's O-LAMM integrates core Monolithic Optical Structure Technology™ (M.O.S.T) and precision Beam Steering Technology, creating a compact and robust 3D laser-scanning system for in situ metrology. O-LAMM’s line-scanning system can track multiple targets at high speed, using retro-reflective cooperative markers on robotic end-effectors or other moving devices.

O-LAMM uses a network of laser units that work together through triangulation, to measure the positions of retro-reflective markers, providing robust, accurate 6-degrees- of-freedom (6-DOF). This compact system maintains arc-second accuracy and operates at 100 Hz scanning speeds.

It is an essential component for Industry 4.0 applications such as automated manufacturing and robotics. It provides vital, real-time information and can be applied to a wide range of measurement tasks. PLX’s O-LAMM is a scalable device that significantly reduces waste, downtime, and setup costs.

PLX can tailor O-LAMM to your specific needs, including mounting configurations and environmental resilience, providing a versatile solution for precision measurement and alignment needs.