RETROREFLECTOR SELECTOR

- All Metal Hollow Retroreflectors™

All-Metal Hollow Retroreflectors (AMHRs) are designed to withstand high temperatures (>400°C), high magnetic fields, and high radiation. -

Ultra Low-Profile Retroreflector™ (ULPR™)

ULPR™ is a cutting-edge ultralight compact retroreflector with rugged stability, and they are offered in a range of accuracy options and configurations. -

Omni Wave Hollow Retroreflector™ (OWHR™)

For a laboratory environment where the Retroreflector needs to be protected from the elements. -

Hard-Mount Retroreflector™ (HMHR™)

Designed for applications where the unit is mounted inside an instrument. -

Ultra Stable Hard-Mounted Retroreflectors™ (USHM™)

Designed to offer the utmost in mounting and mechanical stability. - Coating Specification Chart

| PROPERTIES | All Metal | Ultra Low-Profile | Omni Wave | Hard Mount | USHM |

| Weight | Heaviest | Very Light | Heavy | Very Light | Light |

| Overall Size | Small | Smallest | Large | Small | Small |

| Apex Location Control | Good | Good | Fair | Excellent | Excellent |

| Vacuum Compatible | Excellent | Excellent | Not Standard | Not Standard | Excellent |

| Mounting Stiffness | Excellent | Excellent | Fair | Good | Excellent |

| Mechanical Stability | Excellent | Excellent | Excellent | Excellent | Excellent |

| Thermal Stability | Good | Excellent | Good | Very Good | Excellent |

| Operating temperature range | Widest | Wide | Wide | Wide | Wide |

| Vibration | Excellent | Very Good | Good | Very Good | Excellent |

| Shock Resistance | Excellent | Very Good | Excellent | Very Good | Excellent |

| Protective Housing | No | Yes | Yes | No | No |

| APPLICATIONS | All Metal | Ultra Low-Profile | Omni Wave | Hard Mount | USHM |

| Metrology | Excellent | Excellent | Excellent | Excellent | Excellent |

| OEM Use | Excellent | Excellent | Fair | Excellent | Excellent |

| Motion Control | Good | Very Good | Good | Excellent | Excellent |

| OEM Interferometry | Good | Good | Good | Excellent | Excellent |

| OEM Spectroscopy | Good | Good | Good | Excellent | Excellent |

| Laboratory | Excellent | Excellent | Excellent | Good | Good |

| Industrial | Excellent | Excellent | Excellent | Good | Good |

| Nuclear Fusion | Excellent | Good | Good | Good | Good |

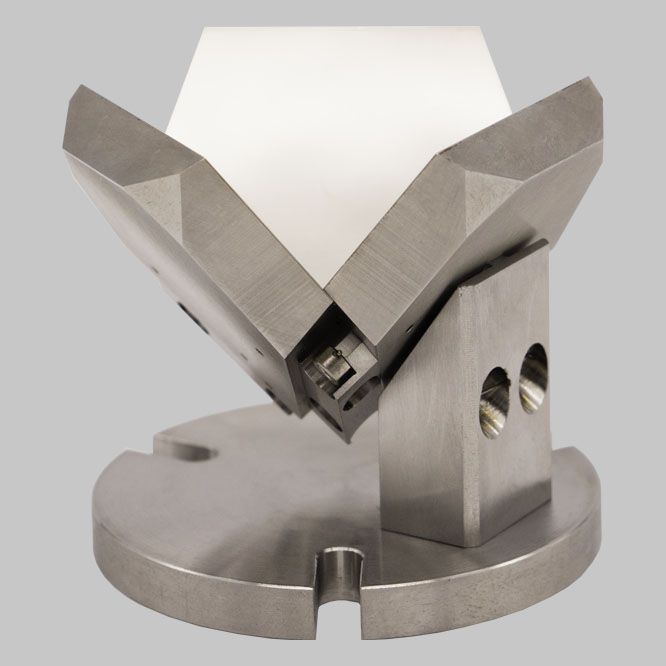

All Metal Hollow Retroreflectors™

The entire unit is made of metal, making it perfect for nuclear fusion applications, and ultra-harsh environments. All-Metal Hollow Retroreflectors (AMHRs) are designed to withstand high temperatures (>400°C), high magnetic fields, and high radiation. They can also withstand high vacuum conditions with no contamination and perform with exceptional shock and vibration resistance under critical operating conditions. Additional extreme uses include volcanic monitoring, Industrial smokestack, and furnace monitoring. The new AMHRs are incredibly versatile and can be configured to work with various metals, like Copper, Aluminum, Stainless Steel, and Molybdenum. PLX engineers can customize an application to fit your specific needs.

The entire unit is made of metal, making it perfect for nuclear fusion applications, and ultra-harsh environments. All-Metal Hollow Retroreflectors (AMHRs) are designed to withstand high temperatures (>400°C), high magnetic fields, and high radiation. They can also withstand high vacuum conditions with no contamination and perform with exceptional shock and vibration resistance under critical operating conditions. Additional extreme uses include volcanic monitoring, Industrial smokestack, and furnace monitoring. The new AMHRs are incredibly versatile and can be configured to work with various metals, like Copper, Aluminum, Stainless Steel, and Molybdenum. PLX engineers can customize an application to fit your specific needs.

Ultra Low-Profile Retroreflector™ (ULPRTM)

The Ultra Low-Profile Retroreflector (ULPR™) series will fit where other retros won’t, it is the ideal retroreflector series with up to a 36% weight reduction over the other retroreflector series. The round shape is ideal for mounting into bores or standard optical bench lens and mirror holders. In the new improved configuration, PLX pushes the cutting-edge of design and performance further with the ULPR's patent pending mounting design. Despite its compact, sleek appearance, the unit is extremely stable over temperature changes, vibration and shock conditions.

The Ultra Low-Profile Retroreflector (ULPR™) series will fit where other retros won’t, it is the ideal retroreflector series with up to a 36% weight reduction over the other retroreflector series. The round shape is ideal for mounting into bores or standard optical bench lens and mirror holders. In the new improved configuration, PLX pushes the cutting-edge of design and performance further with the ULPR's patent pending mounting design. Despite its compact, sleek appearance, the unit is extremely stable over temperature changes, vibration and shock conditions.

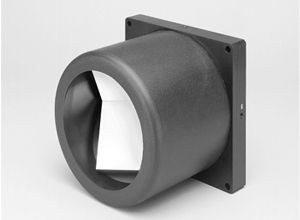

Omni Wave Hollow Retroreflector™ (OWHRTM)

The Omni Wave line of the Hollow Retroreflector was designed for easy handling in a laboratory environment where the Retroreflector needs to be protected from the elements. The Retroreflector is typically mounted in a housing with specially matched cushion providing excellent shock resistance. The base of the Omni Wave is versatile and compatible with all major mounting systems, laboratory tools and setups. As an option, a front window can be installed to keep the optics clean or for application where hermetic sealing is required. An additional available option includes vacuum compatibility that will meet NASA outgassing specification.

The Omni Wave line of the Hollow Retroreflector was designed for easy handling in a laboratory environment where the Retroreflector needs to be protected from the elements. The Retroreflector is typically mounted in a housing with specially matched cushion providing excellent shock resistance. The base of the Omni Wave is versatile and compatible with all major mounting systems, laboratory tools and setups. As an option, a front window can be installed to keep the optics clean or for application where hermetic sealing is required. An additional available option includes vacuum compatibility that will meet NASA outgassing specification.

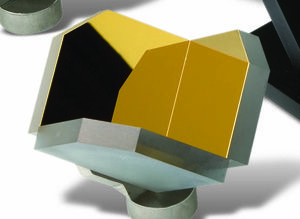

Hard-Mount Retroreflector™ (HMHRTM)

The HM line was designed for applications where the unit is mounted inside an instrument, protected by the instrument enclosure, together with the rest of the instrument’s components. The Hard-Mount Retroreflector is significantly lighter than the Omni Wave (1:5). Therefore it is widely used in applications where the Retroreflector is translating along its optical axis. Typical applications include instruments like Spectrometers, Interferometers, motion control systems and range finders. Also, an available option includes vacuum compatibility for space applications.

The HM line was designed for applications where the unit is mounted inside an instrument, protected by the instrument enclosure, together with the rest of the instrument’s components. The Hard-Mount Retroreflector is significantly lighter than the Omni Wave (1:5). Therefore it is widely used in applications where the Retroreflector is translating along its optical axis. Typical applications include instruments like Spectrometers, Interferometers, motion control systems and range finders. Also, an available option includes vacuum compatibility for space applications.

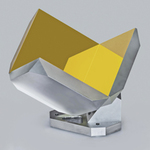

Improved Ultra Stable Hard-Mounted RetroreflectorTM (USHMTM)

The implementation by PLX of a robust Invar mount design adds an extra measure of stability and durability to our USHMs.

The use of Invar, in combination with our new-patented configuration, makes the new USHMs suitable for applications where instruments are exposed to changes in temperature and harsh environments. The design approach incorporated in the improved USHM has been utilized in critical military and space applications.