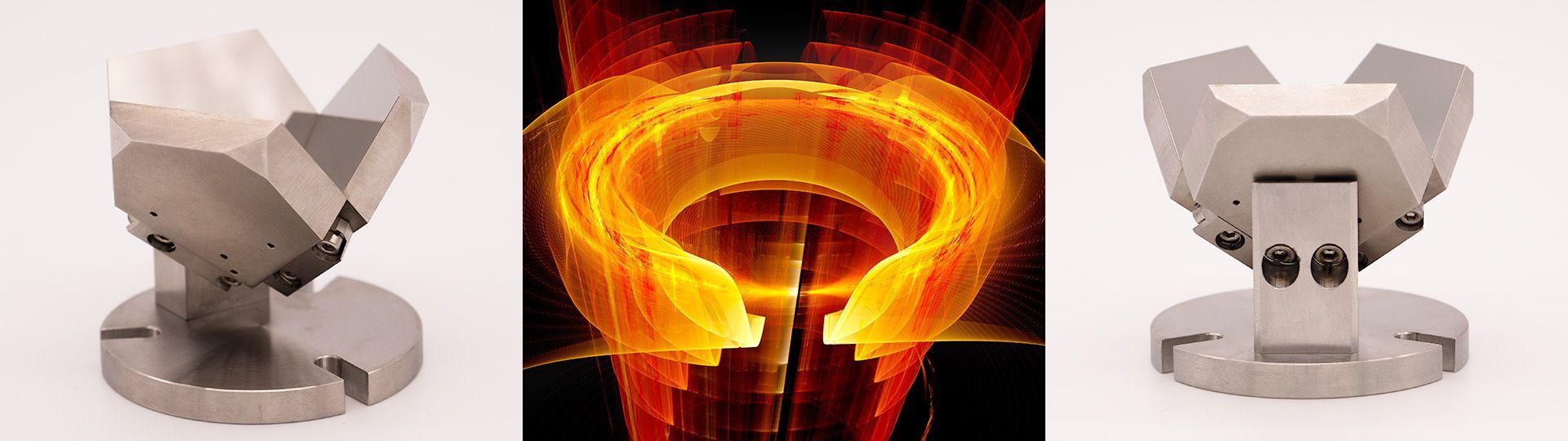

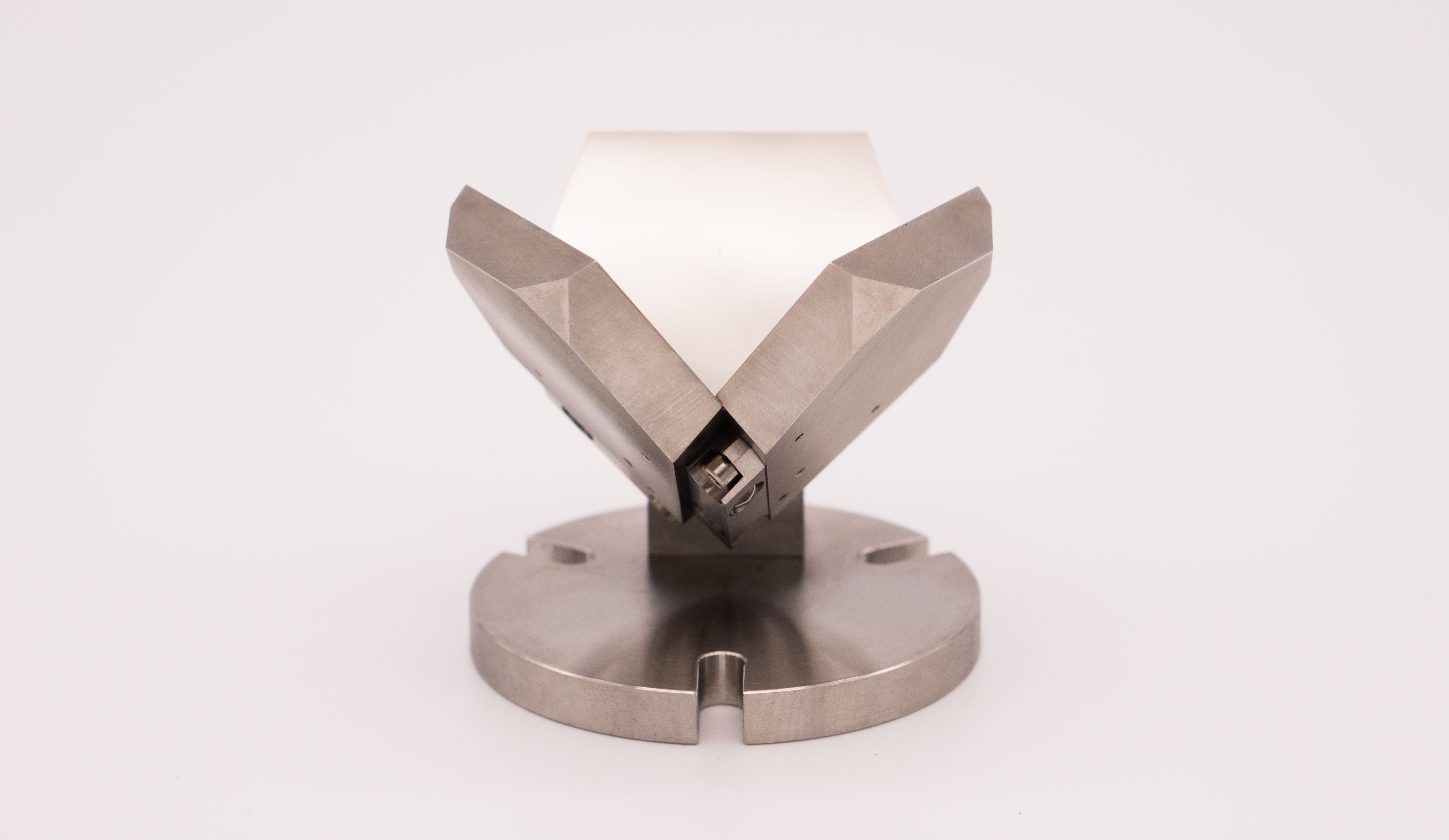

All Metal Hollow Retroreflectors™ (AMHR)

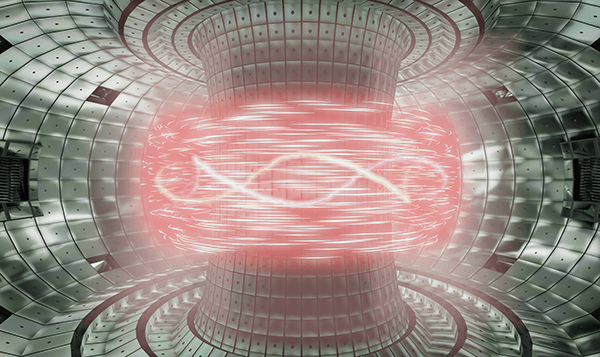

- Perfect for fusion research and extreme environmental conditions.

- Designed to withstand:

High Temperatures (>400°C)

High Magnetic Fields

High Radiation High

Vacuum conditions - Extremely great shock and vibration resistant

- Can work with other metals

- Standard accuracy range: 20 to 100 arc second.

- Higher accuracy than 20 arc second available upon customer request.

- Customized applications are available.

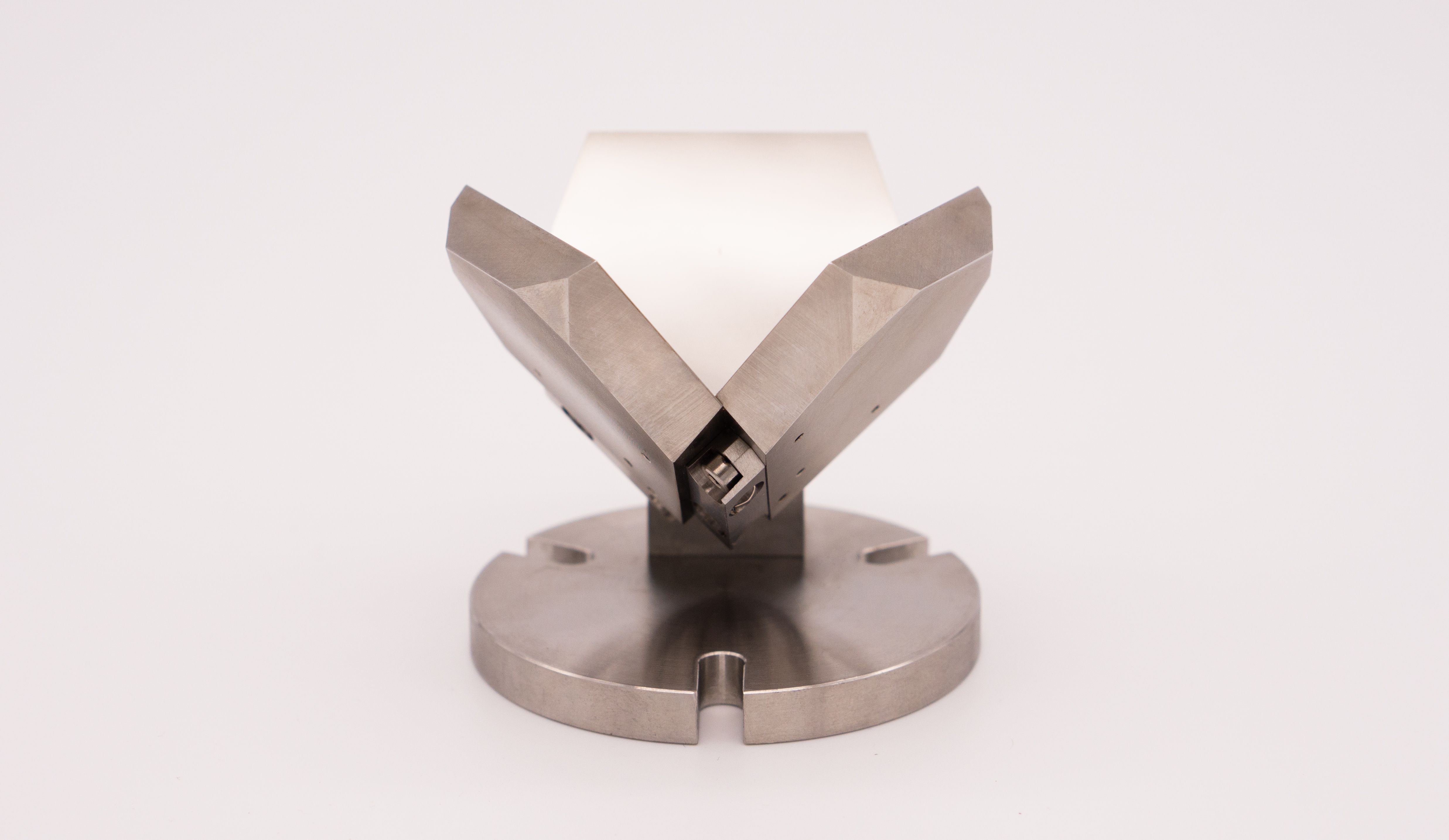

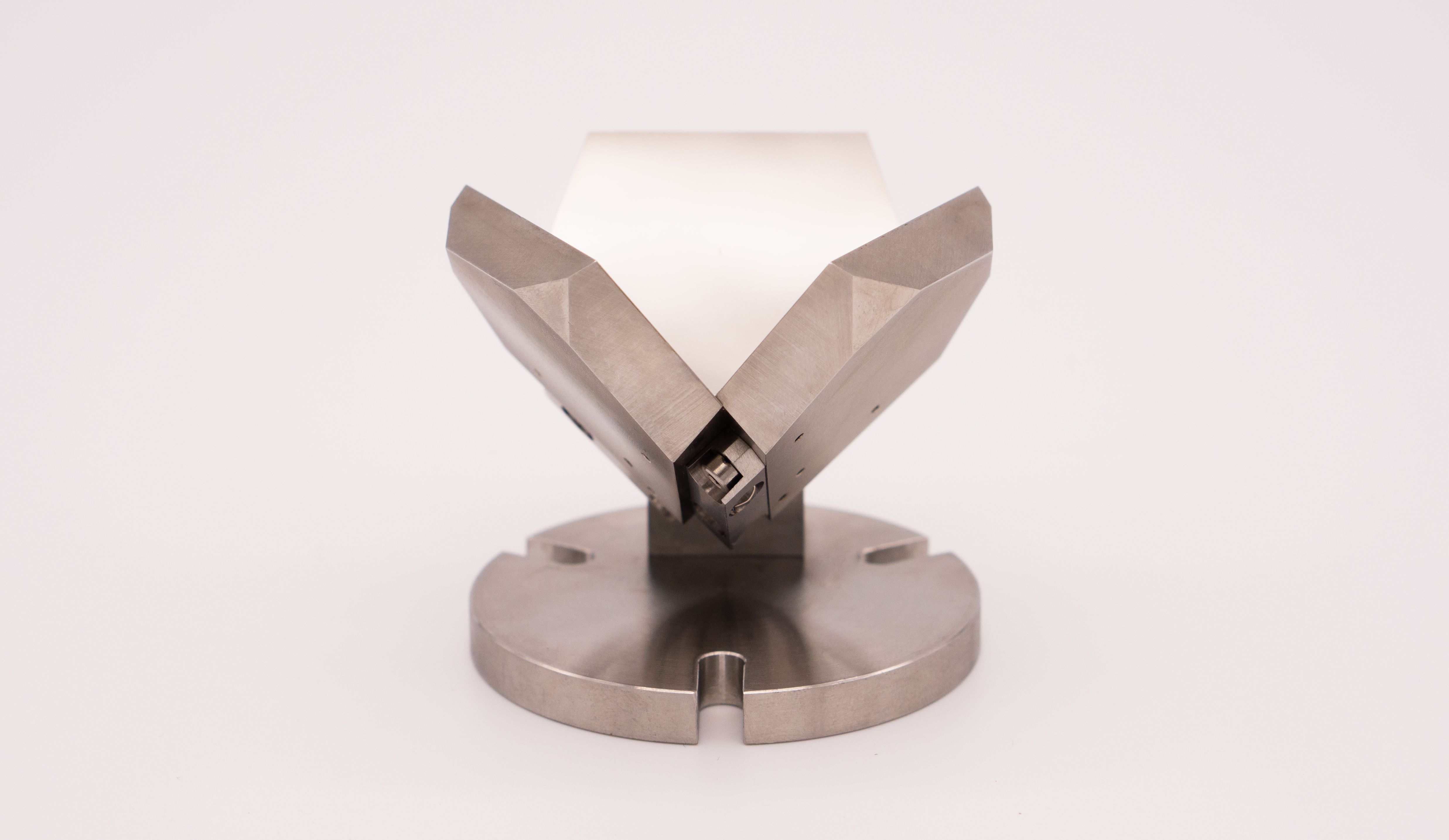

Hollow Retroreflectors

The entire unit is made of metal, making it perfect for nuclear fusion applications, and ultra-harsh environments.

PLX’s Patent Pending, All-Metal Hollow Retroreflectors (AMHRs) are designed to withstand high temperatures (>400°C), high magnetic fields, and high radiation. They can also withstand high vacuum conditions with no contamination and perform with exceptional shock and vibration resistance under critical operating conditions.

Additional extreme uses include volcanic monitoring, Industrial smokestack, and furnace monitoring.

Customized applications.

The new AMHRs are incredibly versatile and can be configured to work with various metals, like Copper, Aluminum, Stainless Steel, and Molybdenum. PLX engineers can customize an application to fit your specific needs.

PLX is a leader in Hollow Retroreflector technology.

In 1970 PLX invented the hollow retroreflector placing us at the heart of innovation for the NASA manned and unmanned space exploration missions of the era. Ever since, we’ve been offering the most versatile line of retroreflector products and systems for the defense, space, and industrial/commercial industries.

| Specification Chart | |||

|---|---|---|---|

| Model | Clear Aperture (in/mm) |

Beam Deviation (arc.sec.) |

Weight (grams) |

AMHR-13

AMHR-13

|

1.25in (32mm) | 20 - 100 | 326 |

AMHR-18

AMHR-18

|

1.75in (44mm) | 20 - 100 | 394 |

AMHR-20

AMHR-20

|

2.0in (51mm) | 20 - 100 | 453 |