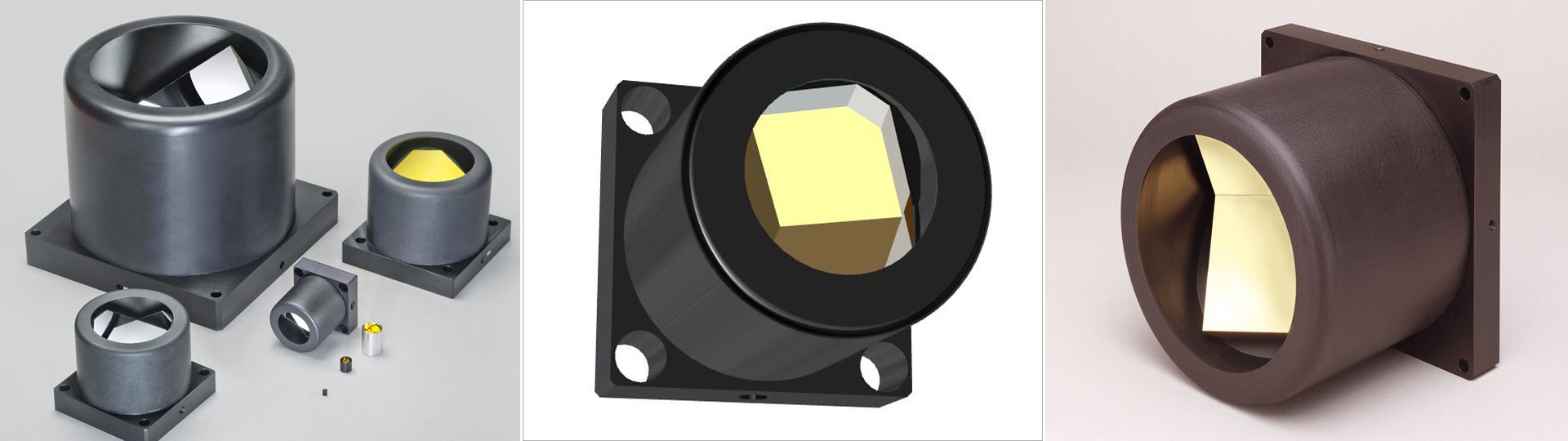

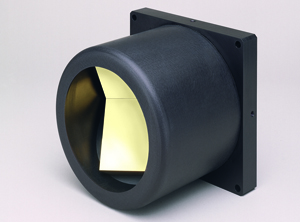

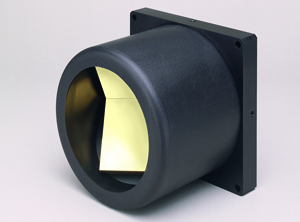

OMNI WAVE HOLLOW RETROREFLECTORS™ (OWHR)

- Parallel incident light returned with great accuracy to the light source regardless of the OWHR's physical orientation.

- Proprietary configuration with cushioned mounting, provides extra protection for better handling and resistance to shock.

- Compatible with all major mounting systems.

- Standard metallic coatings meet all applicable MIL specs, custom coatings available.

- Custom "Knife Edge" design option available upon request, enhances beam quality, eliminates the cause of obscuration.

- RoHS Compliant.

- PLX is a registered ISO 9001 company.

Hollow Retroreflectors

The Omni Wave Hollow Retroreflector (OWHR) can be described as a self-compensating mirror that is totally insensitive to position and movement such as tilt.

Parallel incident light that hits the OWHR will be returned with great accuracy to the light source, regardless of the OWHR’s physical orientation. The OWHR is constructed of three first-surface mirrors assembled by a proprietary process into a mutually-orthogonal inside corner. This configuration eliminates material absorption and chromatic aberration present in prism-type retroreflectors. The mirror coating can be optimized for various spectral ranges, from UV to far IR.

OWHRs are available in standard sizes of 0.08 in (2mm) to 5.0 in (125mm). The units are available in accuracies to 0.5 arc seconds beam deviation and λ/10 wave reflected wavefront error. In the new improved configuration, available only from PLX, the OWHR has a unique, patented, cushion mounting, which makes the unit extremely resistant to shock. The OWHR is provided in a versatile housing, which is compatible with all major mounting systems. The OWHR is available with a broad range of standard metallic coatings which meet all applicable MIL-specs. Unprotected metallic coatings are especially suited to interferometric applications. Custom coatings are available upon request.

| Specification Chart | ||||

|---|---|---|---|---|

| Model | Clear Aperture (in/mm) |

Beam Deviation (arc.sec.) |

Exiting Wavefront (p.v.633nm) |

Weight (grams) |

|

|

0.08/2 | 30.0 | 0.35 | 0.06 |

|

|

0.16/4 | 30.0 | 0.55 | 0.07 |

|

|

0.25/6 | 20.0 | 0.60 | 0.8 |

|

|

0.5/12.7 | 3.0 - 15.0 | 0.30 - 0.90 | 5.9 |

|

|

1.0/25 | 0.5 - 30.0 | 0.10 - 3.50 | 108 |

|

|

1.5/38 | 0.5 - 30.0 | 0.10 - 5.25 | 330 |

|

|

2.0/51 | 0.5 - 30.0 | 0.15 - 7.00 | 454 |

OW-25

OW-25

|

2.5/63 | 0.5 - 30.0 | 0.25 - 9.00 | 772 |

OW-50

OW-50

|

5.0/127 | 0.5 - 30.0 | 0.45 - 18.0 | 3860 |